C2 PROJECT

C2 Photo Album

album:October 2017

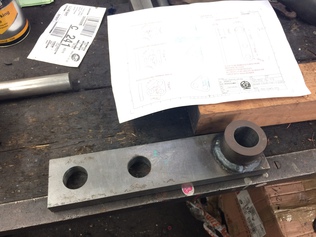

Milling out the holes in a brake block carrier, to accept Iglidur bushes. The clamping arrangement ensures a consistent position of the hole relative to the brake block.

There were 15 of these to do: 10 new fabricated ones, 2 Chinese cast iron, and 3 Chinese cast steel. One will be a spare (the loco and tender together have 14 wheels).

Milling the holes in a brake equalising triangle.

Taliesin and Linda double-headed one of the FR service trains on Sunday. Several of the C2 Project Group were involved in keeping the service running over the weekend.

The brake hanger production line.

Dave supervises Alasdair, as he drills the holes in the brake reaction bracket.

Chris marks out a brake lateral control bracket, ready for drilling and shaping.

The brake ratio link, with boss welded on and holes milled out in the correct positions, but before the corners were rounded off.

Matt does the final cleaning-up of a brake hanger. These are now all ready for painting.

We forgot to take a photo of the spring safety brackets. This photo was taken just a couple of feet below them, showing the most frequent resident of the C2 shed!

Erle has already painted one motion bracket, and is giving the other a final wipe-down before painting.

The 10 new brake block carriers complete and ready for bushing. Carol had kindly painted these since our previous working party.

Alan welds the bosses on to a brake hanger.

The two completed motion brackets, in primer. They will be painted red eventually.

Components for the brake reaction bracket assembled for welding.

Dave welds up the brake reaction bracket.